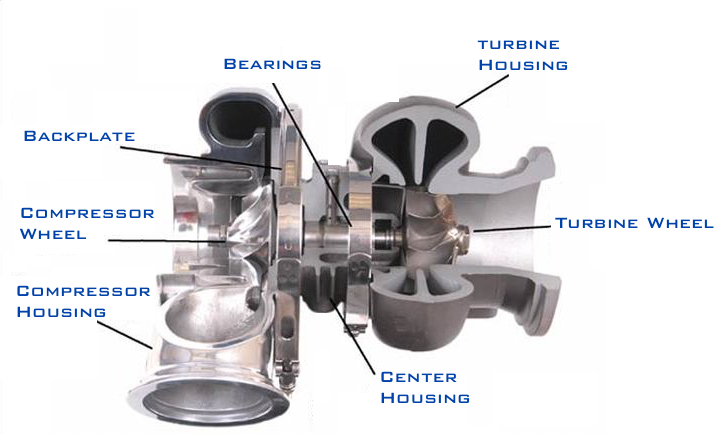

As you can see by the photo there are 7 key areas of focus when rebuilding your Turbocharger.

1. TURBINE WHEEL: The exhaust Turbine Wheel is where it all starts moving. Exhaust from the engine hits the Turbine Wheel and makes the main shaft spin. Turbine wheel designs on most models are more than adequate to feed higher power levels without upgrades. So modifications to the Turbine wheel are often unneeded. Many times simply upgrading to a proper billet style impeller working in conjunction with the factory Turbine wheel will show the best performance per dollar spent.

2. TURBINE HOUSING: Heat generated in this area can cause the Turbine Housing to get red hot. Cracks can form and you can get an exhaust leak and even lose boost, even small cracks can create warpage or housing deformation that can cause catastrophic damage or loss of boost or Turbocharger longevity. Inspection of this area is very critical.

3. CENTER HOUSING: The Center Housing is where oil is fed from the engine to and through this area to keep everything lubed. This oil also helps cool this area down as it gets real hot as temperature transfers from the Turbine Housing. There is a seal in this area that keeps oil from the engine from being pumped into the impellers and causing excessive oil burning. So proper cleaning and proper installation of this seal AND selecting the proper seal material for the application is critical.

4. BEARINGS: The Bearings located along the Turbine shaft allow the shaft to spin freely. High quality bearings and the proper preload is everything to allow the turbo to make boost fast and keep from creating excessive heat (due to excessive pre-load or low quality bearings).

5. BACKPLATE: The Backplate or thrust washer takes the load created by the impeller as it creates boost. So this area being properly square and properly clearanced means everything when you are building a Turbocharger that needs to last.

6. COMPRESSOR WHEEL: The Compressor wheel is responsible for taking the rotational force created by the exhaust as it hits the Turbine Wheel and drawing in air and creating boost. An upgraded Compressor wheel is one of the biggest improvements in Turbocharger operation that you can make. Air being drawn in requires some real critically and properly sized complex shapes that cast Compressor wheels can’t duplicate with the same required strength and shape as a Billet Impeller wheel. So big gains in immediate power and boost can be seen by upgrading to a higher quality Compressor Wheel.

7. COMPRESSOR HOUSING: The Compressor housing needs inspected for cracks and casting/core shift flaws, even simple ledges in this area can create turbulence that harms the creation of boost and air flow to the engine. We offer porting services to correct any of these flaws and remove these ledges as a result of core shift.